1. Principle

Liquid cooling is currently the best cooling technology. The main difference from traditional air cooling is the use of a liquid cooling charging module + equipped with a liquid cooling charging cable. The principle of liquid cooling heat dissipation is as follows:

2. Core advantages

A. High-pressure fast charging generates more heat, has good liquid cooling, and has low noise.

Air cooling: It is an air cooling module + natural cooling charging cable, which relies on heat exchange of air to reduce the temperature. Under the general trend of high-voltage fast charging, if you continue to use air cooling, you need to use thicker copper wires; in addition to the increase in cost, it will also increase the weight of the charging gun wire, causing inconvenience and safety hazards; moreover, air cooling cannot be wired Cable core cooling.

Liquid cooling: Use liquid cooling module + liquid cooling charging cable to take away heat through the cooling liquid (ethylene glycol, oil, etc.) flowing through the liquid cooling cable, so that small cross-section cables can carry large current and low temperature rise; on the one hand, it can strengthen It dissipates heat and improves safety; on the other hand, because the cable diameter is thinner, it can reduce weight and make it easier to use; in addition, because there is no fan, the noise is almost zero.

B. Liquid cooling, can work stably in harsh environments.

Traditional piles rely on air heat exchange to cool down, but internal components are not isolated; the circuit boards and power devices in the charging module are in direct contact with the external environment, which can easily cause module failure. Moisture, dust and high temperature cause the module annual failure rate to be as high as 3~8%, or even higher.

Liquid cooling adopts full isolation protection and uses heat exchange between the coolant and the radiator. It is completely isolated from the external environment and extends the service life of the equipment. Therefore, the reliability is much higher than that of air cooling.

C. Liquid cooling reduces operating costs, increases service life, and reduces life cycle costs.

According to Huawei Digital Energy, traditional piles work in harsh environments for a long time, and their service life is greatly reduced, with a life cycle of only 3 to 5 years. At the same time, mechanical components such as cabinet fans and module fans are not only easily damaged, but also require frequent cleaning and maintenance. Manual visits to the site are required at least four times a year for cleaning and maintenance, which greatly increases site operation and maintenance costs.

Although the initial investment of liquid cooling is relatively large, the number of subsequent maintenance and repairs is less, the operating cost is lower, and the service life is more than 10 years. Huawei Digital Energy predicts that the total life cycle cost (TCO) will be reduced by 40% in 10 years.

3. Main components

A. Liquid cooling module

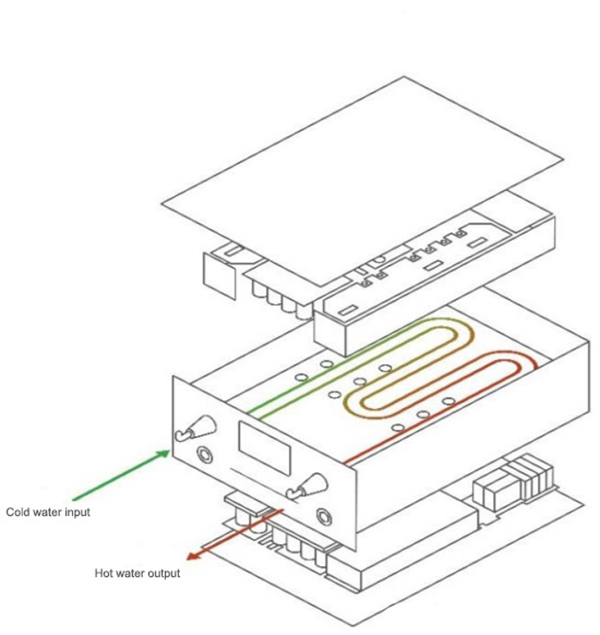

Heat dissipation principle: The water pump drives the coolant to circulate between the interior of the liquid-cooled charging module and the external radiator, taking away the heat of the module.

At present, the mainstream 120KW charging piles in the market mainly use 20KW and 30KW charging modules, 40KW is still in the introduction period; 15KW charging modules are gradually withdrawing from the market. As 160KW, 180KW, 240KW or even higher power charging piles enter the market, the matching 40KW or higher power charging modules will also usher in wider applications.

Heat dissipation principle: The electronic pump drives the coolant to flow. When the coolant passes through the liquid-cooling cable, it takes away the heat of the cable and charging connector and returns to the fuel tank (to store the coolant); then it is driven by the electronic pump to dissipate through the radiator. heat.

As mentioned earlier, the traditional method is to expand the cross-sectional area of the cable to reduce cable heating, but there is an upper limit to the thickness of the cable used by the charging gun. This upper limit determines the maximum output current of the traditional supercharger to 250A. As the charging current continues to increase, the heat dissipation performance of liquid-cooled cables of the same thickness is better; in addition, because the liquid-cooled gun wire is thin, the liquid-cooled charging gun is nearly 50% lighter than a conventional charging gun.

If want to know more about this, please feel free to contact us.

Tel: +86 19113245382 (whatsAPP, wechat)

Email: sale04@cngreenscience.com

Post time: Apr-14-2024