If the electric vehicle architecture is upgraded to 800V, the standards of its high-voltage devices will be raised accordingly, and the inverter will also be replaced from traditional IGBT devices to SiC material MOSFET devices. The cost of the inverter itself is second only to the battery components. If you upgrade to SiC, the cost will go up to another level.

But for OEMs, the application of silicon carbide generally not only considers the cost of power devices, but more importantly, the cost changes of the entire vehicle. Therefore, it is important to find a balance between the cost savings brought by SiC and its high cost.

As far as SiC is concerned, the first person to try it was Tesla.

In 2018, Tesla replaced IGBT modules with silicon carbide modules for the first time in Model 3. At the same power level, the package size of silicon carbide modules is significantly smaller than that of silicon modules, and switching losses are reduced by 75%. Moreover, if converted, using SiC modules instead of IGBT modules can increase system efficiency by about 5%.

From a cost perspective, the replacement cost increased by nearly 1,500 yuan. However, due to the improvement of vehicle efficiency, the installed battery capacity has been reduced, saving costs on the battery side.

This can be regarded as a big gamble for Tesla. Its huge market volume offsets the cost. Tesla also relied on this big bet to seize the technology and market of 400V battery systems.

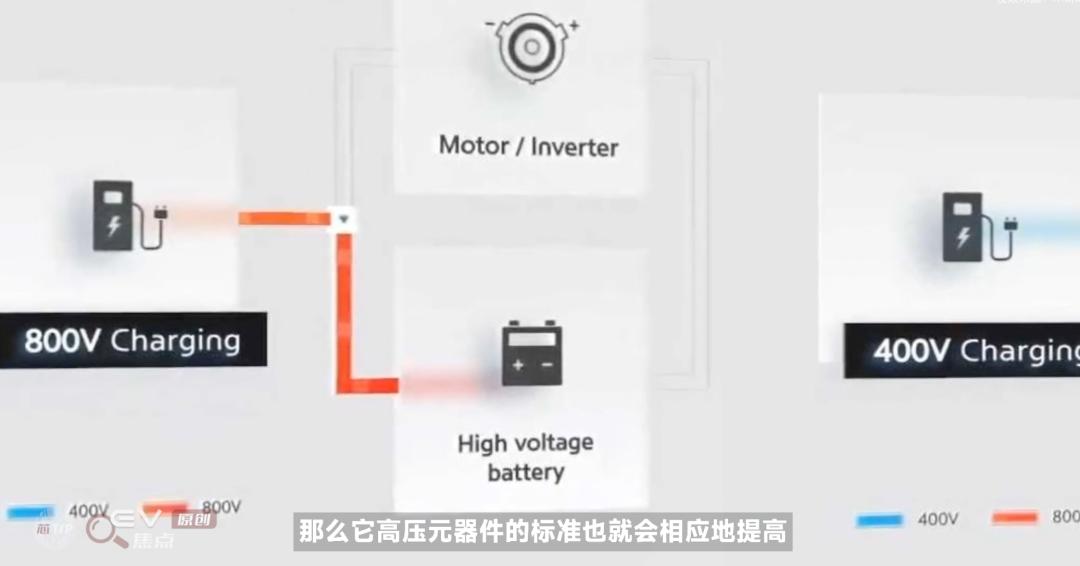

In terms of 800V, Porsche took the lead in equipping the all-electric Taycan sports car with an 800V system in 2019, setting off an arms race for the 800V high-voltage architecture of electric vehicles.

There’s something “inappropriate” about analyzing costs from a Porsche perspective. After all, it focuses on the luxury car effect and focuses on the premium of a brand.

But in terms of technology development and application, this is a major project that affects the whole body. For example, under 800V high-voltage charging, the voltage of the battery pack must be relatively increased to 800V, otherwise it will be burned due to the large charging current. In addition, it not only involves the charging system, but also the battery system, electric drive system, high-voltage accessories and wiring harness system, affecting the starting, driving, air conditioning use of the vehicle, etc.

If want to know more about this, please feel free to contact us.

Tel: +86 19113245382 (whatsAPP, wechat)

Email: sale04@cngreenscience.com

Post time: Mar-19-2024